Blackwater mining project constitute a mining project of New Gold, and located on the northern flanks of Mount Davidson in Nechako Plateau, approximately 160 kilometers southwest of the city of Prince George, 110 kilometers southwest of the town of Vanderhoof in central British Colombia. The project is located approximately 450 kilometers north of New Gold’s New Afton project.

New Gold Inc mining project of this currently in the environmental assessment phase comprises 75 mineral tenures totaling 305.78 square kilometers, and has a total area of property 227 mineral claims covering an area of 1,046.78 square kilometers. The project is appealing and close to infrastructure, the terrain is characterized by rolling hills, the project is accessible by road and access to low cost hydro power is with the construction of a 230 kV transmission line.

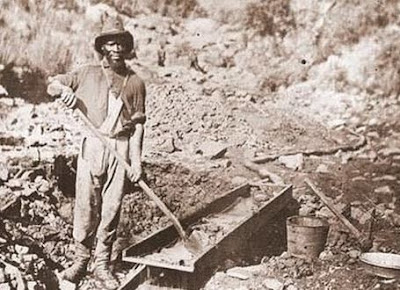

History Of Gold Projects Blackwater

The Blackwater Project area has been actively explored since in 1973 by Granges Inc from streams draining the Mt.Davidson area with the discovery of anomalous concentrations of silver, lead, and zinc in silt samples taken. History of the workmanship of the project includes soil geochemistry, geophysics and reverse circulation and diamond drilling.

The Blackwater Project area has been actively explored since in 1973 by Granges Inc from streams draining the Mt.Davidson area with the discovery of anomalous concentrations of silver, lead, and zinc in silt samples taken. History of the workmanship of the project includes soil geochemistry, geophysics and reverse circulation and diamond drilling.

Richfield’s work on the Blackwater Gold Project began in 2009 when the company recognized the bulk gold potential on the property. In March 2009 Richfield optioned the Davidson and Dave claims from Silver Quest Resources Ltd. and the Rozek family respectively.

The initial mineral resource estimate for its Blackwater project was published in March 2011 and was on 25,263 meters of drilling in 77 holes on the area. An updated mineral resource estimate was prepared in September 2011 and has an additional 71 holes (24,660 meters) March estimate, bringing the total number of core drilling up to 148 (49 223 meters).

Released indicated and Inferred mineral resource estimate in March 7, 2012 presents drill results to December 2011. It is estimated an indicated resource of 5.5 million ounces of gold and an inferred resource of 2.3 million ounces of gold 0.4 grams per tonne cut - off grade

Mining projects Blackwater reported mineral resource in March 31, 2013 within a conceptual pit shell at gold equivalent cut-off values reported 0.3-0.4 grams per tonne. The deposit contains measured and indicated mineral resources for the direct processing of 306 million tonnes at 0.88 grams per tonne gold and 5.8 grams of silver per ton, which representing 8.6 million ounces of gold and 57.5 million ounces of silver.

Moreover, the measured and indicated mineral resources suitable for storage and the future of the mine processing contains 91 million tonnes with 0.30 grams per tonne gold and 4.3 grams of silver per ton, which representing 0.9 million ounces of gold and 12.6 million ounces of silver.

Moreover, the measured and indicated mineral resources suitable for storage and the future of the mine processing contains 91 million tonnes with 0.30 grams per tonne gold and 4.3 grams of silver per ton, which representing 0.9 million ounces of gold and 12.6 million ounces of silver.

Conforms to the CIM (as defined at the ending of the publication) this mineral resource estimate is compliant with definition standards required pursuant to National Instrument 43-101 and is based on a geological block model that contains 286,966 individual assays from 309,516 meters of core of 1,003 drill wells at a nominal distance of 25 meters to 50 meters.

Assay data density is sufficient to classify the mineral resource when the measured and indicated confidence levels as necessary to support the estimation of a mineral reserve. The drill Gap database was supported by approximately 80,000 quality assurance / quality control (QA / QC) check sample supports assays.

Geology & Mineralization In Blackwater project

The Blackwater project within the Stikine Terrane of Inter Montane Belt of central British Columbia. The Stikine Terrane includes Jurassic to Early Tertiary magmatic arc and the associated sedimentary rocks. The Blackwater deposit hosted by a sequence of intermediate and felsic volcanics belonging to the Late Cretaceous Kasalka Group. These rocks overlain by Eocene age post-mineral volcanics belonging to the Ootsa Lake Group and backed by basinal clastic rocks of the Late Jurassic Bowser Lake Group

The Blackwater project within the Stikine Terrane of Inter Montane Belt of central British Columbia. The Stikine Terrane includes Jurassic to Early Tertiary magmatic arc and the associated sedimentary rocks. The Blackwater deposit hosted by a sequence of intermediate and felsic volcanics belonging to the Late Cretaceous Kasalka Group. These rocks overlain by Eocene age post-mineral volcanics belonging to the Ootsa Lake Group and backed by basinal clastic rocks of the Late Jurassic Bowser Lake Group

A well-developed system of northeasterly, northwesterly and northerly striking faults cutting the whole package and acts as the main control to gold-silver mineralization in the region. Quaternary glacial, colluvial and alluvial obscure most of the bedrock in the immediate project area.

gold and silver mineralization at Blackwater occurs obtrusive within an intermediate sulphidation, epithermal gold-silver system that takes place within two kilometers of a cluster of mineralized porphyry centers the same Late Cretaceous stratigraphic Kasalka group.

gold and silver mineralization at Blackwater occurs obtrusive within an intermediate sulphidation, epithermal gold-silver system that takes place within two kilometers of a cluster of mineralized porphyry centers the same Late Cretaceous stratigraphic Kasalka group.

Host rocks within the deposit are pervasively hydrofractured, pyritized and changed to a mixture of silica and sericite. The mineralization is typified by gold-bearing polymetallic sulfides (pyrite, sphalerite, marcasite, pyrrhotite) as disseminations and porosity infillings in the fragmentary unit of the deposit.

Mineralization is strongly controlled by the northwest and northeast extending zones of of shearing and tectonic brecciation. The deposit is bounded by post-mineral trench forming fault in the north and south. A major north-south trending fault transects the orebody, it is divided into two distinct geological domains integral part of the mineral resource block model.

Mineralization is strongly controlled by the northwest and northeast extending zones of of shearing and tectonic brecciation. The deposit is bounded by post-mineral trench forming fault in the north and south. A major north-south trending fault transects the orebody, it is divided into two distinct geological domains integral part of the mineral resource block model.

The feasibility study for the project in 2014, New Gold identified several areas of potential gold mineralization over 1,100 square kilometer property package. New Gold is currently leading his focus for more gold and silver resources in several kilometers of the known epithermal mineralization at Blackwater and the recently discovered porphyry copper-molybdenum mineralization in the south.

Video Blackwater Project New Gold Inc